Presentation

The FISSAC project – Fostering Industrial Symbiosis for a Sustainable Resource Intensive Industry across the extended Construction Value Chain – involved stakeholders at all levels of the construction and demolition value chain to develop a methodology, and software platform to facilitate information exchange, that can support industrial symbiosis networks and replicate pilot schemes at local and regional levels.

Project co-funded by the European Commission under the Horizon 2020 programme, 2015 - 2020.

FISSAC aimed to create a model to support industrial symbiosis networks, in the form of both a methodology and a software platform facilitating information exchange.

The ambition of the project was to develop a flexible model that can be replicated in different regions and other value chain scenarios.

The model was based on three sustainability pillars:

- Environmental (with a life-cycle approach)

- Economic (business plan and market analysis)

- Social (taking into consideration stakeholder engagement and impact on society).

FISSAC aimed to demonstrate the effectiveness of the processes, services and products at different levels.

INDUSTRIAL SYMBIOSIS

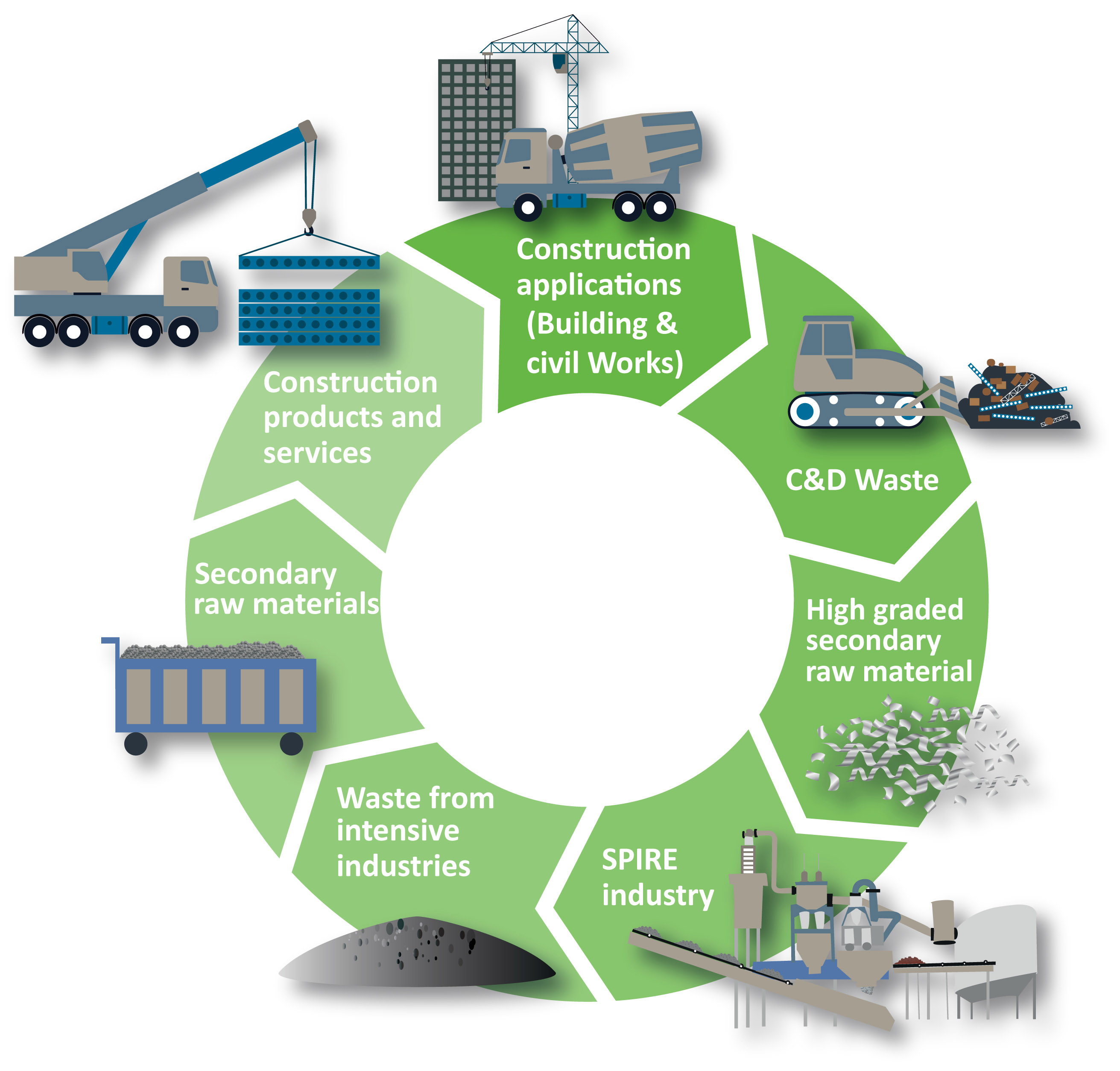

Industrial symbiosis is a form of brokering to bring companies together in innovative collaborations, finding ways to use the waste from one as raw materials for another.

Local or wider co-operation in industrial symbiosis can reduce the need for virgin raw material and waste disposal, thereby closing the material loop – a fundamental feature of the circular economy and a driver for green growth and eco-innovative solutions. It can also reduce emissions and energy use and create new revenue streams. The FISSAC project worked with stakeholders to understand these aspects and build a model and supported systems that endeavoured to overcome the challenges.

FISSAC Software Platform

The FISSAC Software Platform aimed to go beyond existing software by integrating their capabilities and adding network analysis functionalities to assess the roles of partners within the industrial symbiosis network and evaluate the success of overall operation using social network analysis (SNA) methodologies.

A knowledge repository was developed to be used as data source for dynamic geo-database web service and provide semantic information on graphical layers regarding climatic, socio economics, financial, energy, material, mobility and all the geo-referenced data useful to the stakeholders. The FISSAC platform is used for the evaluation of the material, energy flow as well as evaluating the environmental impacts and cost of the studied flows.

Several reports were elaborated including the main project results. To find out more visit the library section of the project website (link).

Activities

A methodology and a software platform were developed in order to implement the innovative industrial symbiosis model in a feasible scenario of industrial symbiosis synergies between industries (steel, aluminium, natural stone, chemical and demolition and construction sectors) and stakeholders in the extended construction value chain.

It guides how to overcome technical and non-technical barriers as well as standardisation concerns to implement and replicate industrial symbiosis in a local/regional dimension.

It envisages three interventions:

- Manufacturing processes: demonstration of closed-loop recycling processes to transform waste into valuable acceptable secondary raw materials;

- Product validation: demonstration of the eco-design of eco-innovative construction products in pre-industrial processes, under a life-cycle approach;

Industrial symbiosis model: replicability assessment of the model through Living Lab concept.

Partners

FISSAC’s project coordinator was ACCIONA (Acciona Infrastructures S.A., ES) and the project partners were:

- ACR+, Association of Cities and Regions for Sustainable Resource Management (BE)

- UNE, Asociacion Española de Normalización y certificación (ES)

- CSIC, Agencia estatal Consejo Superior de Investigaciones Cientificas (ES)

- AKG Gazbeton, AKG Gazbeton Isletmeleri Sanayi Veticaretcaret AS (TR)

- Befesa, Befesa Salzschlacke GMBH (DE)

- British Glass Manufacturers Con., British Glass Manufacturers Confederation Limited (UK)

- CSM, RINA Consulting S.p.A. - Centro Sviluppo Materiali S.p.A. (IT)

- D’Appolonia, RINA Consulting S.p.A. | D’Appolonia S.p.A. (IT)

- EKODENGE, EKODENGE Muhendislik Mimarlik Danismanlik Ticaret Anonim Sirketi (TR)

- Ecodek® Specialist Building Products Ltd. (UK)

- FUNAB, Fundación Agustín de Betancourt (ES)

- FENIX, Fénix TNT s.r.o (CZ)

- Feralpi, Feralpi Siderurgica S.p.A. (IT)

- GEONARDO, Geonardo Environmental Technologies Ltd (HU)

- GTS, Glass Technology Services Ltd (UK)

- TRI, Ingenieurbuero Trinius GMBH (DE)

- HIFAB, HIFAB AB (SE)

- KERABEN, KERABEN GRUPO SA (ES)

- OVAM*, Openbare Vlaamse Afvalstoffenmaatschappij (BE)

- RINA, RINA Services S.p.A. (IT)

- RISE, RISE Research Institutes of Sweden AB - SP Sveriges Tekniska Forskningsinstitut AB (SE)

- CBI, RISE Research Institutes of Sweden AB | CBI Betonginstitutet AB (SE)

- SIMBIOSY, Simbiosy - Simbiosi Insutrial SL (ES)

- TÇMB (TCMA), Turkiye Cimento Mustahsilleri Birligi (TR)

- TECNALIA, Fundación Tecnalia Research & Innovation (ES)

* ACR+ member